Introduction: The "ChatGPT Moment" for Machines That Move

For years, the public’s perception of humanoid robots was defined by YouTube clips of backflips and choreographed dances. While impressive, these demos often lacked the industrial "grit" required for the messy, unpredictable world of manufacturing. However, as we cross the threshold of early 2026, the narrative has shifted fundamentally. We are no longer talking about what robots might do; we are witnessing what they are doing.

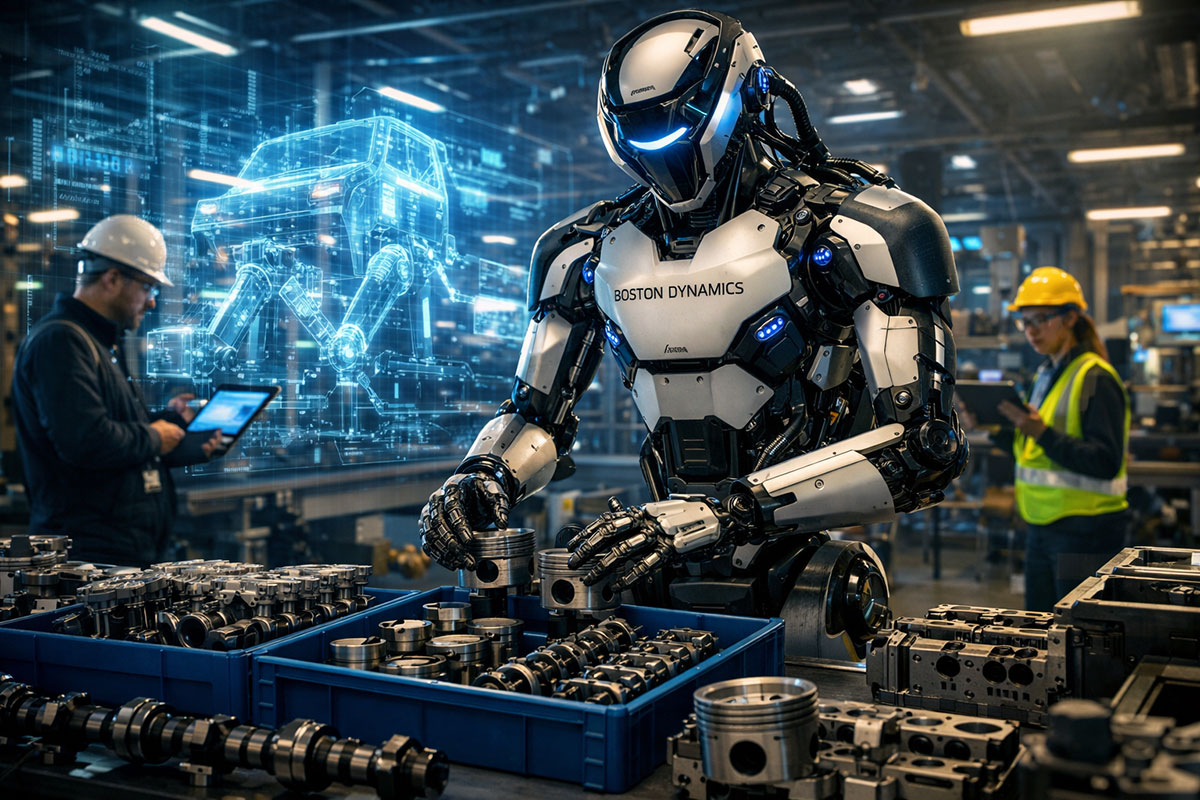

At CES 2026, the world watched as NVIDIA CEO Jensen Huang proclaimed the arrival of the "ChatGPT moment for Physical AI." This isn't just marketing hyperbole. The convergence of Vision-Language-Action (VLA) models, the rollout of NVIDIA Alpamayo, and the commercial field tests of the all-electric Boston Dynamics Atlas at Hyundai’s Metaplant America represent a tangible leap in how we interact with the physical world.

"Physical AI is the next frontier. It’s the transition from AI that thinks in silicon to AI that acts in the world. In 2026, the factory floor is the first true proving ground for this intelligence." — Senior Strategy Report, TrendFlash 2026.

In this deep dive, we go beyond the hype to explore the technical architecture, the economic stakes, and the specific platforms—like Boston Dynamics’ Atlas at Hyundai—that are redefining the 2026 industrial landscape.

The Atlas Evolution: Why the "Electric Move" Changed Everything

The transition from the iconic hydraulic Atlas to the all-electric Atlas unveiled in late 2024 was the prerequisite for the 2026 manufacturing surge. While hydraulics offered raw power, they were loud, prone to leaks, and difficult to maintain in a sterile factory environment. The new electric architecture is a masterclass in modern engineering.

Technical Specifications of the 2026 Industrial Atlas

The Atlas currently undergoing field tests at the Hyundai Motor Group Metaplant America isn't just a walker; it's a precision instrument. Key upgrades include:

- 56 Degrees of Freedom (DoF): Advanced rotational joints that allow the robot to move in ways humans cannot, such as 180-degree torso rotations to pick parts without moving its feet.

- 110 lbs (50 kg) Lift Capacity: Designed for heavy-duty "kitting" and sequencing tasks that traditionally cause repetitive strain injuries in human workers.

- Swappable Battery System: Moving beyond the 4-hour continuous runtime limit, the 2026 Atlas can autonomously return to a dock, swap its own battery, and return to the line in under 90 seconds.

- IP66 Rating: Ensuring the robot can handle the dust, heat, and occasional washdowns of a real-world steel or automotive plant.

| Feature | Traditional Industrial Robot | 2026 Physical AI (Atlas) |

|---|---|---|

| Environment | Fixed, Caged, Structured | Dynamic, Unstructured, Human-Shared |

| Programming | Complex Scripting/G-Code | Natural Language & VLA Models |

| Flexibility | Single Task (Welding/Painting) | General Purpose (Sequencing to Assembly) |

| Safety | Zero-Human Interaction Zones | Real-time Obstacle Avoidance (Cobot AI) |

The Foundation: Understanding VLA Models and NVIDIA Alpamayo

What makes these robots "smart" isn't just the hardware; it’s the brain. In 2025, we saw the rise of Large Language Models (LLMs). In 2026, we are seeing the dominance of Large World Models (LWMs) and Vision-Language-Action (VLA) frameworks.

The VLA Framework Explained

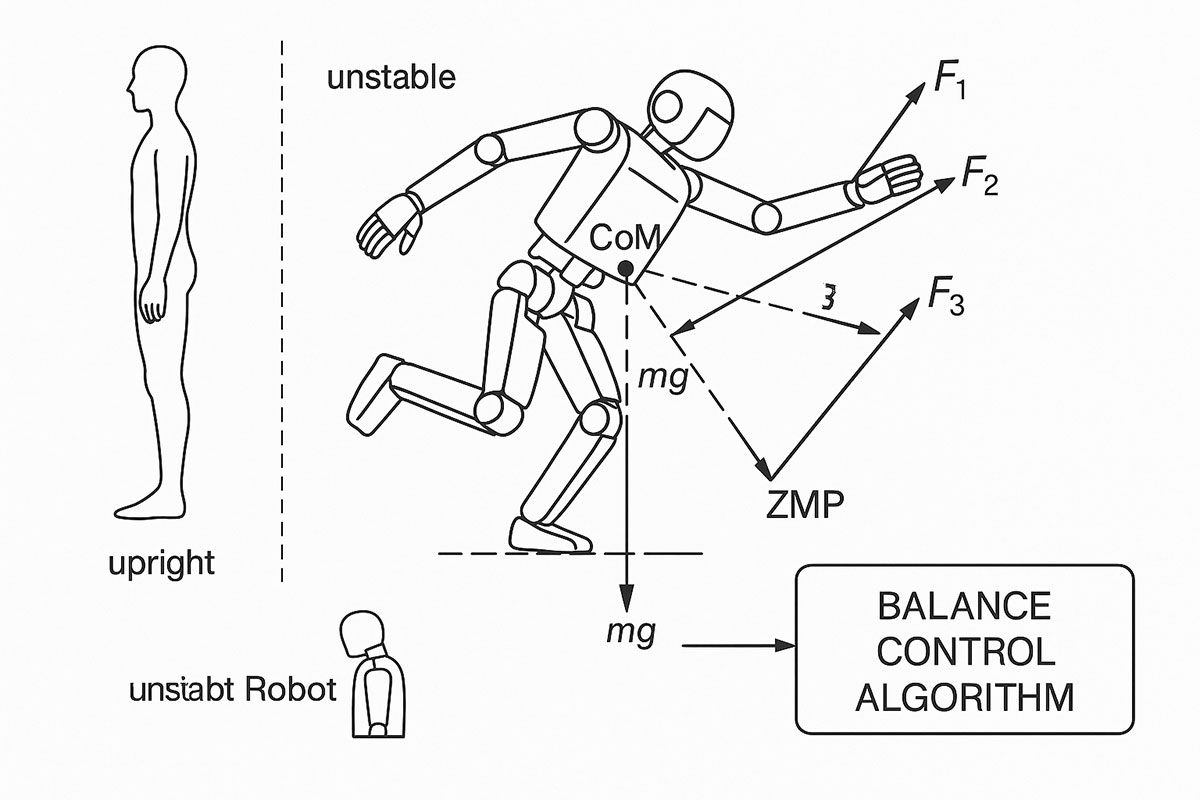

Traditional robots were "if-then" machines. A VLA model, however, processes data in three simultaneous streams:

- Vision: High-resolution 3D spatial mapping (DINOv2/SigLIP encoders) to understand object depth and material properties.

- Language: The ability to take a command like "Find the scratched fender and move it to the bin" without pre-defined coordinates.

- Action: Translating that understanding into motor torques and joint movements at frequencies of 120Hz to 400Hz.

NVIDIA Alpamayo: The Operating System of Physical AI

Central to this revolution is NVIDIA Alpamayo, the reasoning-based platform launched at the start of 2026. Alpamayo 1, a 10-billion-parameter model, serves as the "teacher" for these robots. By utilizing AlpaSim (the simulation environment), engineers can train an Atlas to perform 10,000 hours of sequencing in just a few hours of real-time GPU compute. This "Simulate-then-Procure" shift has slashed the ROI timeline for factory automation from years to months.

For more on how these agents are talking to each other, see our report on the Agent Internet and MCP protocols.

Field Report: Hyundai’s Factory Floor in 2026

The most significant development of January 2026 is the deployment of Atlas at the Hyundai Robotics Metaplant Application Center (RMAC). Unlike previous pilots that were relegated to clean rooms, these robots are now handling parts sequencing—the complex task of picking specific components from a chaotic bin and placing them in a specific order for the main assembly line.

This is a "high-variance" task that has baffled traditional robotics for decades. The VLA-powered Atlas uses its tactile-sensing hands to feel the weight and orientation of a part, adjusting its grip in real-time if a piece slips. This is the difference between a machine that breaks things and an agent that solves problems.

However, this transition isn't without friction. As these robots enter the workforce, the debate over mass unemployment vs. the "Human-Plus" era has reached a fever pitch. At Hyundai, the strategy isn't replacement; it's augmentation. Humans are moving into Robot Technician roles, focusing on training the AI and handling the "long-tail" exceptions that even the best VLA models can't solve yet.

Strategic Implementation: The Roadmap to a Smart Factory

If you are a manufacturer looking at the 2026 landscape, the path to Physical AI integration requires a mindset shift. You cannot simply "plug in" a humanoid robot into a 1990s infrastructure.

1. Establish a Digital Twin Architecture

Before a physical Atlas touches your floor, you must have a high-fidelity digital twin. Using tools like NVIDIA Isaac Sim or Microsoft's Rho-alpha, you can validate the robot’s pathing and safety protocols in a virtual space. This eliminates "CapEx guessing."

2. Implement Agentic Workflows

The true power of Physical AI is realized when the robot is part of an Agentic AI network. When a sensor on a CNC machine detects a vibration anomaly, it should autonomously signal the Atlas to retrieve the necessary replacement part and alert the human technician simultaneously.

3. Navigate the Regulatory Minefield

2026 is a year of legal transition. With Trump’s Executive Order on AI safety clashing with various state laws, manufacturers must ensure their robotic fleets are compliant with evolving data privacy and worker safety standards. Transparent "chain-of-thought" auditing in models like Alpamayo 1 is becoming a regulatory requirement, not just a feature.

Challenges: The Road to 2030

Despite the "Best Robot" awards and viral success, Physical AI still faces significant hurdles:

- Data Density: A single humanoid robot generates terabytes of sensory data per hour. Managing this "Digital Nervous System" requires massive edge-computing investment.

- Energy Sovereignty: As factories scale their robotic fleets, the demand for power is skyrocketing. We are seeing a move toward on-site hybrid solar and self-healing energy infrastructure to support 24/7 autonomous operations.

- The "Long Tail" Problem: While Atlas can handle 95% of standard factory tasks, the remaining 5%—handling broken parts, spills, or sudden power surges—remains a human-centric domain.

Conclusion: Beyond the Demos

The era of "Robotics for Show" ended with the 2025 holiday season. As we move deeper into 2026, Physical AI is becoming the "New Normal" for global manufacturing leaders. The partnership between Hyundai, Boston Dynamics, Google DeepMind, and NVIDIA has created a blueprint for the future: a world where digital intelligence has finally found its physical form.

Whether it’s the all-electric Atlas kitting parts in Georgia or VLA-powered cobots helping SMEs in Italy, the message is clear: The hype is over. The work has begun.