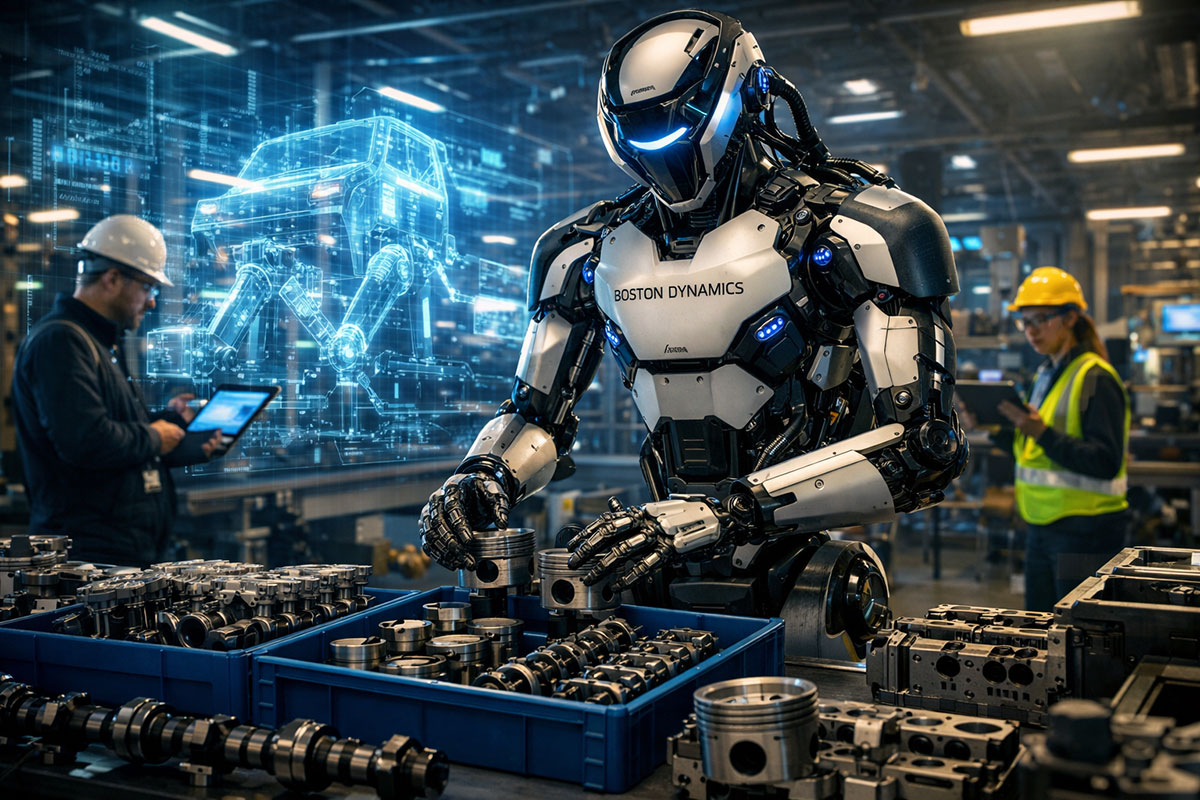

Boston Dynamics' Atlas at Hyundai: The Humanoid Robot Era Begins

The humanoid robot era isn't coming—it's here. Boston Dynamics' Atlas just walked onto a real factory floor at Hyundai's Georgia facility, marking the first commercial deployment of a humanoid robot in manufacturing. With 99.8% reliability, superhuman flexibility, and the ability to learn new tasks in a single day, Atlas represents a fundamental shift in how factories operate. But here's what nobody's talking about: this isn't about replacing workers. It's about redefining what manufacturing jobs look like.

TrendFlash

Boston Dynamics' Atlas at Hyundai: The Humanoid Robot Era Begins

Introduction: From Viral Videos to Factory Floors

For over a decade, Boston Dynamics captivated the internet with videos of humanoid robots doing backflips, dancing, and performing parkour stunts. Those weren't just impressive party tricks—they were engineering milestones, each movement representing layers of AI, mechanical precision, and biomechanical innovation. But on January 4, 2026, CBS's “60 Minutes” pulled back the curtain on something far more significant than parkour. Atlas, Boston Dynamics' humanoid robot, walked onto the production floor at Hyundai's manufacturing facility in Savannah, Georgia, and got to work.

This moment matters because it marks the transition from research laboratory to industrial reality. For the first time in robotics history, a humanoid robot isn't just demonstrating capabilities in a controlled environment—it’s executing real manufacturing tasks with 99.8% reliability in a live factory setting. The industrial humanoid robot era has officially begun.

“This isn’t a demo reel anymore. Atlas is on a real shift, doing real work, next to real people.”

If you’ve been following broader automation trends, this shift connects directly to how agentic AI and autonomous systems are quietly rewiring workflows across industries, from software to logistics. For a deeper dive into the AI side of that transformation, you can explore posts like Beyond Chatbots: The Quiet Rise of Agentic AI on Trendflash and the broader AI landscape in the AI News & Trends category.

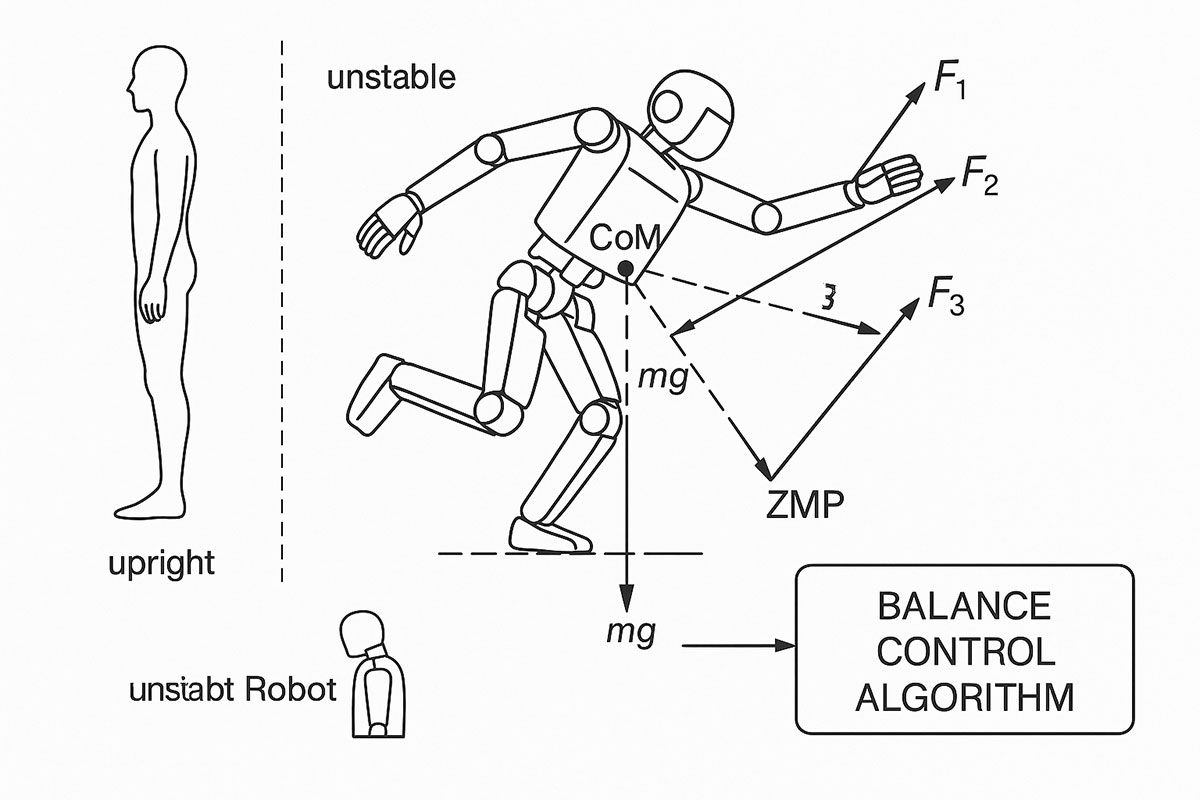

What Is Atlas, Really—and Why Does It Matter?

Before diving into what this deployment means for manufacturing and employment, it's essential to understand what Atlas actually is.

The latest electric Atlas stands about 1.9 meters (6.2 feet) tall and weighs roughly 90 kilograms (198 pounds). These dimensions aren’t cosmetic. Atlas is purpose-built to fit existing human-centric infrastructure:

- Workstation heights

- Aisle widths on factory floors

- Reach distances to bins, racks, and conveyors

Unlike earlier prototypes that chased a “human-like” silhouette, this production-focused Atlas optimizes for industrial utility.

Key Design Highlights

- 56 degrees of freedom across its joints, enabling:

- 360-degree head rotation without moving its torso

- Deep bending at waist and knees to reach low bins

- Smooth, multi-axis motion in tight spaces

- Extended reach of about 2.3 meters (7.5 feet), giving it an advantage over most human operators for overhead and extended tasks

- Four‑fingered hands with sophisticated tactile sensing for secure grip and precise placement

- All-electric architecture, a critical shift from earlier hydraulic designs

That last point is crucial. Earlier generations of Atlas were engineering marvels but operational nightmares for production environments. Hydraulic systems are complex, leak-prone, and maintenance-heavy. The new Atlas:

- Eliminates hydraulic fluid and most associated failure modes

- Improves drivetrain efficiency from roughly 60–70% to 85–90%

- Reduces the number of unique parts, aligning more closely with standard automotive supply chains

In other words, this isn’t a robot designed to impress YouTube. It’s a robot designed to survive—and add value—on a factory floor.

What Atlas Actually Does at Hyundai’s Plant

At Hyundai's Savannah facility, Atlas isn’t performing gymnastics. It’s doing something every manufacturing leader recognizes as both essential and mind-numbingly repetitive: parts sequencing.

Parts sequencing is the process of organizing, retrieving, and staging components in the exact order required by the assembly line. Get this wrong, and you introduce bottlenecks, misbuilds, and costly rework. Get it right, and the line flows smoothly.

Atlas is currently responsible for tasks such as:

- Navigating a staging area to locate bins and pallets

- Lifting and placing components onto mobile dollies and racks

- Organizing those parts in the correct sequence and orientation

- Adjusting dynamically when something is slightly out of place

Hyundai’s field tests revealed a few eye-opening results:

- Atlas performed its assigned tasks about 18% faster than previous baselines.

- It maintained ±2 mm precision placing parts—well within automotive tolerances.

- When a part wasn’t where it “should” be, Atlas could re-plan its motion in under 400 ms and still complete the task safely.

To make the impact easy to scan, here’s a quick view of the metrics that matter most on a production line:

| Atlas Performance Metric | Value | Why It Matters for Factories |

|---|---|---|

| Precision in part placement | ±2 mm | Reduces misbuilds and rework |

| Task completion speed | ~18% faster vs baseline | Boosts throughput without extra headcount |

| Reliability (uptime) | 99.8% | Minimizes unplanned downtime |

| Continuous lift capacity | ~30 kg (66 lbs) | Handles many engine and drivetrain components |

| Peak lift capacity (short bursts) | ~50 kg (110 lbs) | Supports heavier sub-assemblies when needed |

| Learning time for a new task | < 24 hours | Rapid deployment to new workflows |

| Battery self-swap time | < 3 minutes | Enables 24/7 operation with rotation |

| Operating temperature range | –20°C to 40°C | Works in typical warehouse and light outdoor conditions |

This isn’t a generic industrial arm fenced off behind yellow lines. Atlas walks the same floors as human workers, operates in semi-structured environments, and handles variability traditional robots struggle with.

If you’re curious how computer vision and robotics are already reshaping similar environments, the post Computer Vision in Warehouse Automation: How AI Is Revolutionizing Logistics in 2025 on Trendflash shows just how quickly these technologies are converging with real-world operations.

How Atlas Learns: From VR Demonstrations to Fleetwide Skills

One of the most disruptive aspects of Atlas is not the hardware, but the learning pipeline behind it.

Instead of hand-coding every movement:

-

Engineers demonstrate tasks in VR.

They wear headsets and use controllers to perform the task virtually—lifting, rotating, and placing parts as a human would. -

AI models absorb motion data.

Atlas’s control systems capture trajectories, forces, and constraints from these demonstrations. -

Simulation runs thousands of variations.

In a virtual environment, the system stress-tests slight variations: different part positions, slight misalignments, new bin layouts. -

The robot learns a robust policy.

It finds motion plans that work reliably across many realistic scenarios. -

Orbit distributes the skill.

Boston Dynamics’ orchestration platform, often described as the “central brain” for the fleet, packages the new skill and pushes it to every Atlas unit connected to the network.

When one Atlas learns, every Atlas learns.

This knowledge network effect is a radical departure from traditional automation. With conventional industrial robots, each cell typically needs its own programming and tuning. With Atlas, skill creation is centralized, deployment is global.

For companies exploring how to orchestrate many AI-driven systems—not just robots—posts like Beyond Automation: How Agentic AI Is Rewiring Business for a 2025 Workforce help frame why this “plan once, execute everywhere” model is becoming so important.

Deployment Timeline: From Pilot to Production Reality

It’s easy to dismiss any high-profile robotics story as a one-off demo. Atlas at Hyundai is different because there is a clear, staged deployment roadmap.

2026: Real-World Proving Ground

- Atlas units begin working at Hyundai’s Savannah, Georgia facility.

- Additional deployments go to Google DeepMind and select partner labs.

- Key goal: validate reliability, safety, and integration with existing workflows.

2028: Deep Integration into Hyundai’s Metaplant

- Atlas becomes embedded in parts sequencing and related material-handling workflows.

- The focus shifts from “Can it work?” to “How do we scale this safely and profitably?”

- Other automakers—Toyota, BMW, and others—request onsite demos and pilot projects.

2030 and Beyond: From Sequencing to Assembly

- Atlas expands beyond staging and sequencing to component assembly tasks, where precision and adaptability become even more critical.

- Annual production ramps, with Hyundai and partners targeting tens of thousands of units over the decade.

Analysts studying the humanoid robot market expect the sector to grow from around $2.9 billion in 2025 to over $15 billion by 2030, driven largely by industrial deployments like this one.

The Labor Question: 50K+ Manufacturing Jobs Affected—But How?

Whenever robots enter a factory, one question dominates: What happens to the people working there?

The reality is more nuanced than simple “robots take jobs” headlines.

The Numbers Behind the Fear

- Automation has already played a role in eliminating over 1.7 million manufacturing jobs in the US since 2000.

- Studies on the broader automation wave suggest that tens of thousands of roles tied to repetitive manufacturing tasks are affected every year.

- With deployments like Atlas, projections for 50K+ manufacturing roles impacted in 2026 alone—through restructuring, reshaping, or outright replacement—are not far-fetched.

But “impacted” does not always mean “eliminated.”

What Gets Automated First

Atlas is being pointed squarely at work that is:

- Highly repetitive

- Physically demanding or ergonomically risky

- Structurally similar across shifts and sites

In other words: the same type of tasks that hurt human backs, knees, and shoulders for decades.

Typical at-risk job profiles include:

- Parts runners and manual sequencers

- Heavy material handlers

- Repetitive pick-and-place line workers

On the flip side, roles likely to grow include:

- Robot maintenance technicians

- Automation and workflow engineers

- Quality and process analysts

- AI and robotics integration specialists

If you're thinking about your own role or your team’s, it’s worth pairing this with content like AI Job Transformation 2025: The Data-Driven Guide to Roles at Risk and Future-Proof Skills, which breaks down which skills transition best into an AI- and automation-heavy economy.

Reliability, Uptime, and the 99.8% Claim

The claim of 99.8% reliability sounds impressive, but what does it mean in practice?

In manufacturing terms, that reliability number typically refers to the percentage of scheduled operating time during which the system performs as expected:

- 99.8% uptime means only 0.2% downtime due to failures or unscheduled maintenance.

- Across a 40‑hour work week, that’s about 1.44 hours of downtime per robot.

- Over a year, it’s roughly 75 hours of unplanned downtime—often manageable with smart scheduling, redundancy, and modular repair.

Boston Dynamics pushes this further with modular design:

- Individual joints, hands, sensors, and actuators can be swapped without removing the entire robot from the line.

- Common failure modes found in earlier hydraulic Atlases—like wires breaking in rotating joints—have been engineered out of the new electric design.

In effect, Atlas is not just reliable—it’s maintainable, which is just as critical for production leaders staring at OEE dashboards all day.

How Fast Could Humanoid Robots Spread in Factories?

No manufacturer can afford magical thinking about adoption. Timelines matter for capital planning, workforce strategy, and competitive positioning.

A realistic three‑phase adoption curve for humanoid robots like Atlas looks something like this:

Phase 1 (2026–2028): Proving at the Top Tier

- Early deployments at Hyundai, Google DeepMind, and a small set of flagship customers.

- Humanoids stay concentrated in high-value, high-visibility use cases.

- Metrics focus on safety, uptime, and interoperability rather than pure cost savings.

Phase 2 (2029–2034): Cost-Driven Expansion

- As production scales and per‑unit costs drop toward the $15,000–20,000 range, more factories can justify adoption.

- Regions with labor shortages and aging populations (Japan, South Korea, parts of Europe) lead the next wave.

- Humanoids spread from automotive into electronics, logistics, and even some highly repetitive areas of pharma and FMCG.

Phase 3 (2035+): Standard Equipment

- Humanoid robots become standard line items in new factory builds—much like traditional industrial arms today.

- Older plants face a choice: retrofit for humanoids or fall behind facilities designed ground-up for human–robot collaboration.

- Workforce planning assumes mixed teams of people, fixed automation, and humanoid systems.

For leaders trying to anticipate this arc, the broader market context around AI, robotics, and infrastructure is covered in posts like AI Infrastructure Arms Race: Inside the Multi-Gigawatt Deals Fueling Next-Gen Models and Computer Vision in 2025: How Robots Are Transforming Manufacturing & Healthcare on Trendflash.

Skills, Reskilling, and the New Factory Workforce

If Atlas is the symbol of a new industrial era, skills are the real currency.

The emerging manufacturing workforce needs a blend of:

- Hands-on technical know‑how (tools, machines, safety)

- Digital skills (data, dashboards, software interfaces)

- AI and automation literacy (understanding what agents and robots can and cannot do)

High‑value roles in the next 5–10 years include:

- Robot maintenance & reliability engineers

- Automation workflow designers who tune sequences for both humans and machines

- Data & operations analysts who interpret production metrics and recommend changes

- AI/agentic workflow orchestrators, who manage fleets of intelligent systems across tools and hardware

If you're mapping a career path—either for yourself or for employees—pairing manufacturing knowledge with AI literacy and automation capability is one of the strongest bets. Trendflash’s posts in AI in Business & Startups and Machine Learning offer a useful foundation here.

Atlas vs. Traditional Industrial Robots: What’s Actually New?

Traditional industrial robots excel at:

- Repetitive, highly structured tasks

- Fixed positions, usually fenced off for safety

- Long production runs with little variation

Atlas brings something different to the table:

- Mobility: It can walk, navigate tight spaces, and operate across multiple workstations.

- Human‑scale form factor: It directly fits into environments and tools built for people.

- Adaptive behavior: With vision and AI reasoning, it can handle variance and mild chaos better than most fixed arms.

- Knowledge sharing: Skills can be broadcast fleetwide via platforms like Orbit.

This doesn’t mean humanoids replace all forms of automation. Instead, they fill the gap between:

- Static robots that need rigid environments

- Human workers who are flexible but limited by physical risk and fatigue

Think of Atlas less as “the new worker” and more as a new kind of tool—one that moves through space, learns, and adapts.

Global Competition: Atlas, China, and the Humanoid Race

The Atlas deployment at Hyundai isn’t happening in a vacuum. At the same time:

- Chinese manufacturers are racing ahead with their own humanoid platforms.

- China already accounts for more than half of global industrial robot installations and is aggressively developing domestic humanoid systems.

- Other automakers and electronics giants are quietly running their own pilot programs.

The stakes are high:

- Countries that master humanoid deployment lock in advantages in productivity, quality, and resilience.

- Those that lag may struggle to compete on cost and flexibility, even if they retain lower labor costs in the short term.

Atlas gives Hyundai—and by extension, South Korea and the US—a credible entry in this race. But the outcome will depend less on any single robot and more on ecosystems: suppliers, skills, software, and integration strategies.

Limitations and Risks: What Atlas Can’t Do (Yet)

Despite the hype, Atlas is not a magic bullet.

Current limitations include:

- Fragility of certain tasks: High‑precision, delicate assembly involving brittle materials still favors skilled human hands.

- Unstructured environments: Truly chaotic spaces with constant, unpredictable change remain challenging.

- Power and maintenance cycles: Even with self-swapping batteries, uptime depends on robust charging and maintenance infrastructure.

- Safety constraints: A 90 kg robot moving with superhuman speed must follow strict safety and interaction protocols.

These limits matter for plant managers making real decisions. In many cases, hybrid solutions—humans, fixed robots, and humanoids together—will outperform any one category operating alone.

The Bottom Line: The Humanoid Era Has Quietly Begun

Boston Dynamics' Atlas stepping onto Hyundai’s Georgia factory floor is more than a robotics milestone. It’s a signal:

- The gap between research video and production reality is closing.

- Humanoid robots are no longer a 2030‑plus fantasy—they’ve entered 2026 planning cycles.

- Manufacturing jobs aren’t disappearing overnight, but the nature of those jobs is changing fast.

For workers, leaders, and investors, the right response isn’t panic—it’s preparation:

- Understand where automation and humanoids fit into your workflow.

- Invest early in skills and reskilling that bridge physical operations with AI literacy.

- Watch the interplay between agentic AI in software and humanoid robots in the physical world—the winning strategies combine both.

And if you want to zoom out beyond robots to the broader shift towards autonomous AI systems acting as “virtual coworkers,” the Trendflash ecosystem already has a growing library of deep dives—from The Rise of AI Agents in 2025: From Chat to Action to The Future of Work in 2025: How AI Is Redefining Careers and Skills—that can help you see where this is all headed next.

For more on how AI and automation are transforming industries, you can browse the latest analyses in the AI News & Trends and Computer Vision & Robotics sections on Trendflash.

Tags

Share this post

Categories

Recent Posts

AI as Lead Scientist: The Hunt for Breakthroughs in 2026

Measuring the AI Economy: Dashboards Replace Guesswork in 2026

Your New Teammate: How Agentic AI is Redefining Every Job in 2026

From Pilot to Profit: 2026's Shift to AI Execution

Related Posts

Continue reading more about AI and machine learning

Physical AI Hits the Factory Floor: Beyond the Humanoid Hype

Forget the viral dance videos. In early 2026, Physical AI moved from the lab to the assembly line. With the electric Boston Dynamics Atlas beginning field tests at Hyundai, we explore the "Vision-Language-Action" models and digital twins turning humanoid hype into industrial reality.

Russia's First AI Humanoid Robot Falls on Stage: The AIdol Disaster & What It Teaches About AI Robotics (November 2025)

On November 10, 2025, Russia's first humanoid AI robot, AIdol, became an instant internet sensation for all the wrong reasons—it collapsed face-first on its debut stage. While the viral video sparked laughter and memes online, the incident reveals profound truths about why humanoid robotics remains one of AI's greatest challenges.

Computer Vision in 2025: How Robots Are Transforming Manufacturing & Healthcare

Explore the real-world applications of computer vision in robotics that are driving unprecedented advancements in manufacturing precision and healthcare outcomes in 2025.