Russia's First AI Humanoid Robot Falls on Stage: The AIdol Disaster & What It Teaches About AI Robotics (November 2025)

On November 10, 2025, Russia's first humanoid AI robot, AIdol, became an instant internet sensation for all the wrong reasons—it collapsed face-first on its debut stage. While the viral video sparked laughter and memes online, the incident reveals profound truths about why humanoid robotics remains one of AI's greatest challenges.

TrendFlash

Introduction: When Innovation Meets Gravity

On November 10, 2025, during a technology showcase at Moscow's Yarovit Hall Congress Centre, the world witnessed one of the most spectacular failures in recent robotics history. Russia's first humanoid AI robot, AIdol, walked onto the stage to the triumphant Rocky theme song, waved to the crowd, and within seconds collapsed face-first onto the floor in a moment that instantly went viral across social media platforms.

The incident wasn't just embarrassing for Russia's fledgling robotics industry—it was educational. As thousands of videos circulated on X (formerly Twitter), TikTok, and YouTube with comments ranging from humor ("it learned to walk from alcoholics") to genuine technical analysis, the AIdol disaster became a masterclass in why humanoid robotics remains one of the most challenging frontiers in artificial intelligence and engineering. This wasn't a random malfunction; it was a fundamental lesson about the engineering complexity that separates working robots from headline-grabbing demonstrations.

What Happened: The AIdol Debut

The robot, developed by Russian startup Idol, stood approximately 1.83 meters (6 feet) tall and weighed about 95 kg (209 pounds). It was presented as an embodiment of Russian AI innovation—a homegrown alternative to Western humanoid robots. According to the company, AIdol integrated movement control, emotion modeling, and interactive dialogue capabilities, relying heavily on Russian-manufactured components (approximately 77 percent of the robot's parts were domestically produced).

The debut was meticulously planned. As the robot emerged from backstage, it began its carefully programmed walk across the platform. It raised its right arm in what appeared to be a friendly wave to the assembled crowd. Then, almost immediately, it staggered. Its balance wavered. Within seconds, it tumbled forward, its face striking the stage floor as assistants rushed to help. Within moments, organizers hastily pulled a black curtain across the stage to shield the fallen robot from view.

The video went viral instantaneously. By the next morning, millions of people worldwide had watched Russia's first AI humanoid robot face-plant on live television. The embarrassment was compounded by how quickly staff attempted to cover up the incident—quite literally pulling a curtain over the mistake, which only made the scene more comedic and memorable for viewers.

The Company's Response: Calibration, Not Catastrophe

In the immediate aftermath, Vladimir Vitukhin, CEO of Idol, faced a barrage of questions from Russian media and international journalists. Rather than dismissing the incident as a total failure, Vitukhin framed it as part of the development process. "This is real-time learning," he explained. "When a good mistake turns into knowledge, and a bad mistake turns into experience."

Vitukhin attributed the fall to calibration issues and insufficient lighting during the event. He emphasized that AIdol was still in its testing phase—not a finished product ready for market deployment. The company temporarily removed the robot from public view to allow engineers to inspect its balance systems and control software.

While this response was professional and measured, it also highlighted a critical gap between what the company was willing to show the public and what the technology could actually deliver. The decision to proceed with a public debut when the robot wasn't ready suggested either overconfidence or pressure to demonstrate progress to investors and the media.

Why Humanoid Robots Keep Falling: The Physics & Engineering

To understand why AIdol fell, and why humanoid robots in general struggle so dramatically with basic locomotion, we need to examine the fundamental engineering challenges involved in bipedal motion—challenges that humans solve automatically but that remain extraordinarily difficult for machines.

The Center of Mass Problem

The most critical factor in humanoid robot balance is the location and management of the center of mass—the theoretical point where all a robot's weight concentrates. For humans, this center of mass sits relatively low in the body and can be dynamically adjusted through small muscle contractions and postural shifts. We maintain balance automatically, using millions of years of evolutionary refinement encoded in our nervous system.

For humanoid robots, the center of mass typically sits much higher on the body, creating a precarious balancing act. Every movement risks shifting this center of mass outside the robot's base of support—the area of contact between its feet and the ground. When this happens, physics takes over, and the robot falls. This isn't a software bug; it's a fundamental physics problem that requires split-second calculations and adjustments.

Research on humanoid balance reveals that only about 0.02 percent of humanoid robots successfully maintain perfect balance across complex movement scenarios. This isn't due to lack of engineering talent; it reflects the genuine difficulty of the problem. A robot must constantly measure its body position, predict future movement, calculate whether its center of mass will remain within its support base, and make continuous micro-adjustments through its actuators—all in real-time.

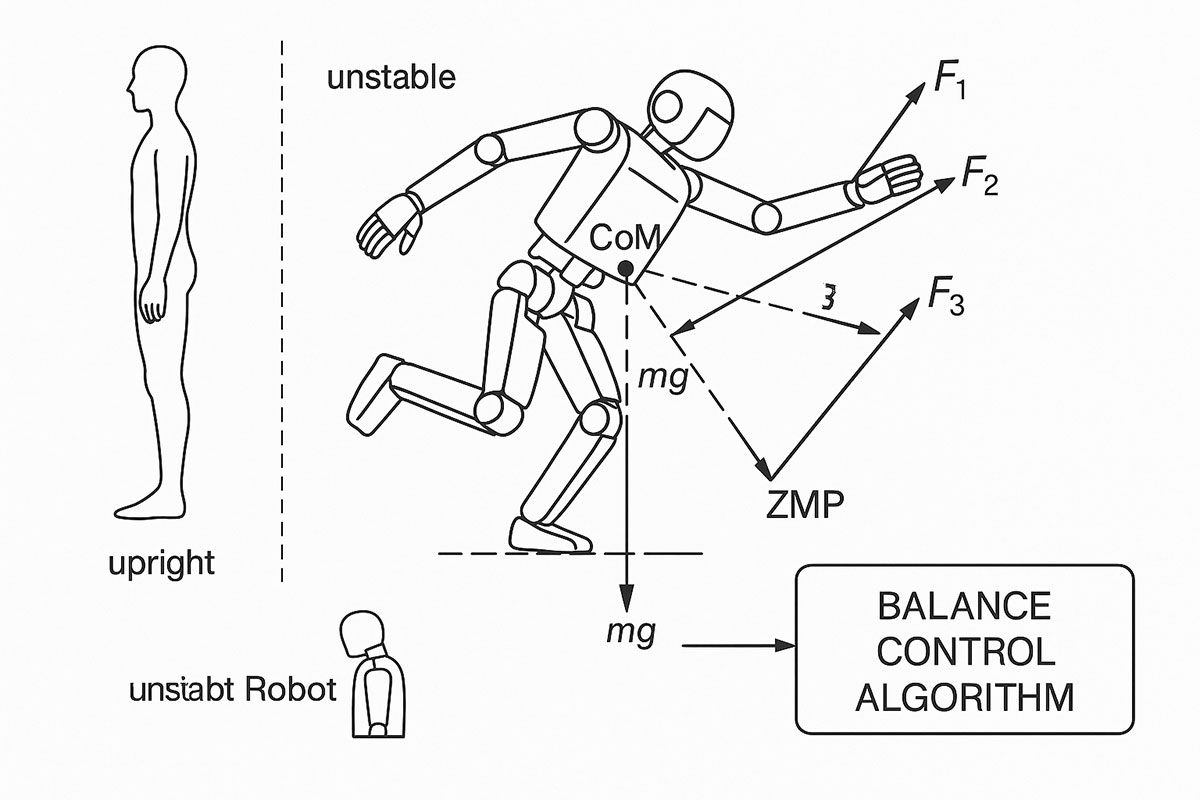

The Zero Moment Point Strategy

To solve this problem, roboticists developed a concept called the Zero Moment Point (ZMP)—a mathematical technique for ensuring that ground reaction forces keep a robot stable. The ZMP tracks the exact point on the ground where the robot's rotational forces balance out to zero. As long as this point stays within the robot's support base (between its feet), the robot remains upright.

However, calculating and maintaining ZMP in real-time is computationally intensive and requires precise sensor feedback. Any delay in sensor response, any miscalibration, or any unexpected environmental condition can cause the ZMP to shift outside the safe zone—resulting in a fall.

Sensor Limitations and Real-World Complexity

Humanoid robots rely on sophisticated sensor arrays—accelerometers, gyroscopes, pressure sensors, and optical encoders—to understand their position and movement. These sensors feed data into control algorithms that make rapid adjustments to joint angles and motor outputs. However, sensors have inherent noise and lag. Environmental factors like uneven flooring, vibrations, or unexpected obstacles can introduce errors that the robot's control system may not anticipate quickly enough.

AIdol's fall likely resulted from a combination of these factors: perhaps the stage lighting affected the robot's visual sensors, calibration errors in its accelerometers introduced inaccurate data about its tilt angle, or the stage flooring wasn't perfectly level, causing one foot to contact the ground differently than predicted.

Dynamic vs. Static Balance

There's a crucial distinction between static balance (standing perfectly still) and dynamic balance (moving while remaining upright). Standing still is relatively easy for a humanoid robot—it's a constrained problem with a fixed center of mass. Moving, however, introduces enormous complexity. Every step involves lifting one foot, shifting weight to the other leg, managing the resulting inertial forces, and then placing the lifted foot down in a new position.

During this dynamic process, the center of mass is constantly moving, and the balance point is constantly shifting. The robot's control system must predict these shifts milliseconds in advance and adjust motor outputs accordingly. This is why humanoid robots often move with mechanical stiffness and awkward gaits—they're calculating and correcting balance continuously, rather than exploiting the fluid, instinctive balance that humans achieve through decades of developmental learning.

How AIdol Compares to International Competitors

The embarrassment of AIdol's failure is sharpened by comparison to robots being developed by well-funded international competitors with much longer development timelines and larger engineering teams.

Boston Dynamics' Atlas

Boston Dynamics' Atlas robot, refined over more than three decades, represents the current apex of humanoid robot athleticism. Standing 1.65 meters tall and weighing 82 kg, Atlas uses hydraulic actuators—systems that provide explosive power and enable rapid, dynamic movements. Recent demonstrations have shown Atlas performing parkour routines, including running, jumping, and executing backflips with apparent ease.

Atlas achieves these feats through sophisticated control algorithms that manage whole-body dynamics and through continuous innovation in mechanical design. However, Atlas is fundamentally a research platform, not a product designed for mass deployment. Each unit is custom-built, featuring complex hydraulic systems that require significant maintenance and external power sources.

Tesla's Optimus

Tesla's Optimus represents a different philosophy—designing a humanoid robot for practical deployment at scale. Standing 1.73 meters tall and weighing just 56 kg (compared to AIdol's 95 kg), Optimus features 40 degrees of freedom (compared to typical designs with fewer articulation points). Most importantly, Optimus is designed from the ground up for manufacturability and deployment in factories and eventually homes.

Tesla leverages its artificial intelligence expertise (developed through autonomous vehicle research) and manufacturing scale. Optimus uses electric actuators rather than hydraulics, providing better energy efficiency and easier maintenance. Recent demonstrations show Optimus moving with increasing fluidity, walking at speeds up to 8.05 km/h—a 30 percent improvement over previous iterations.

What AIdol's Failure Reveals

Compared to these international competitors, AIdol's failure reveals several critical gaps:

Development Timeline: Boston Dynamics and Tesla have development cycles spanning years or decades. AIdol's startup was attempting to demonstrate a working humanoid robot with a much shorter timeline and substantially fewer resources.

Engineering Expertise: The team behind Boston Dynamics includes some of the world's leading roboticists. Tesla can leverage decades of autonomous vehicle development. Idol is a small startup of reportedly just 14 employees, self-funded and working without significant external investment.

Testing and Iteration: Advanced robots undergo thousands of hours of controlled testing before public demonstrations. The fact that AIdol's balance systems failed during its very first public appearance suggests insufficient pre-demo testing, or perhaps demonstration pressure that overrode engineering caution.

Sensor Integration: International competitors use highly refined sensor fusion techniques and custom-built components. AIdol relied on 77 percent domestic components, which may have included less-advanced sensors or different calibration standards.

The Broader Lessons for AI Robotics Development

While AIdol's failure was dramatic, it illuminates important truths about AI robotics development that extend far beyond this single incident.

Embodied AI Remains Fundamentally Different from Language Models

The recent success of large language models like GPT-4 and Claude has created an impression that artificial intelligence has solved "general intelligence." However, embodied AI—artificial intelligence controlling a physical robot in the real world—remains extraordinarily challenging. Language models operate in digital space where computation is cheap and errors are often forgivable. Robots must operate in physical space where mistakes result in visible failure and potential safety hazards.

This distinction explains why a company can create a conversational AI that fools many people, but struggle to build a robot that walks reliably. The problems are fundamentally different.

The Gap Between Research and Production

AIdol's failure also highlights the immense gap between research achievements and production-ready systems. Boston Dynamics and Tesla are acutely aware of this gap. Both companies focus heavily on manufacturing feasibility, supply chain realities, and cost control—not just technical capability.

Idol's emphasis on "77 percent domestic components" suggests a different priority set—perhaps political and economic sovereignty—rather than engineering optimization. While patriotic motivations are understandable, they may have meant using less-optimized components or avoiding best-in-class solutions available internationally.

The Importance of Incremental Development

Successful robotics companies typically follow an incremental development approach: build a simple system, test it extensively in controlled environments, iterate on improvements, test again, gradually increase complexity, and only then demonstrate publicly. A company that skips these steps—jumping directly to public demonstration—risks exactly what happened with AIdol.

The contrast is stark when you consider that Tesla's Optimus improvements (30 percent walking speed increase) were achieved through systematic development cycles, not overnight breakthroughs. Similarly, Boston Dynamics' evolution from earlier Atlas prototypes to the current athletic version took years of iterative refinement.

Where Humanoid Robotics Is Headed

Despite AIdol's failure, the field of humanoid robotics continues advancing rapidly. Several trends suggest where the technology is heading:

Specialized vs. General-Purpose: Rather than attempting to build universally capable humanoids, developers are creating robots optimized for specific tasks. A robot for warehouse work has different balance and dexterity requirements than one for elderly care. Tesla's approach—designing Optimus for manufacturing initially—reflects this trend.

AI-Assisted Learning: Newer robots use machine learning to improve their control algorithms through experience. Rather than hand-coding every balance correction, these systems can learn optimal control strategies through simulation and real-world testing. This approach may help future robots adapt to varied environments more robustly than AIdol could.

Distributed Manufacturing: Tesla's plan to manufacture Optimus at scale reveals recognition that humanoid robots will only become practical when production costs drop dramatically. This requires manufacturing optimization as much as engineering innovation.

Hybrid Approaches: Some developers are exploring hybrid systems that combine human teleoperation (remote control) with autonomous control. This allows humans to handle genuinely difficult situations while the robot handles predictable, repetitive tasks. This middle ground may represent the near-term future of practical robotics.

Why This Matters Now

The November 2025 timing of AIdol's failure carries significance beyond the incident itself. We're at a moment when:

- AI breakthroughs in reasoning models and autonomous systems are generating excitement about AI's general capabilities

- Investors are looking for robotics companies to demonstrate progress

- Geopolitical competition is driving countries to develop domestic AI and robotics capabilities

- Public expectations about AI progress are higher than ever

In this context, highly publicized failures like AIdol's serve as important reality checks. They remind us that despite massive progress in narrow AI applications, embodied AI—robots that must operate reliably in messy physical environments—remains genuinely difficult. Companies overstating progress, or demonstrating systems before they're ready, will face public scrutiny and viral ridicule.

Conclusion: Learning From Failure

Vladimir Vitukhin's statement that the AIdol fall was a "learning experience" was diplomatically accurate. The incident did teach lessons—not just to Idol, but to the entire field of robotics and to investors and observers watching the AI space.

The lesson isn't that Russian robotics is backward or that humanoid robots are impossible. The lesson is that robotics development requires patience, extensive testing, realistic timelines, and humility before the genuine complexity of the problems being solved.

Companies like Boston Dynamics and Tesla succeed not because they've eliminated failure, but because they fail early, learn systematically, and only demonstrate when systems are genuinely ready. AIdol's fall wasn't a catastrophic setback for the field—it was a visible reminder that these standards exist for good reasons.

For the robotics industry moving forward, the AIdol incident serves as both cautionary tale and motivation. Other teams will learn from this public failure, implementing more rigorous testing protocols and being more conservative about public demonstrations. Meanwhile, Idol's engineers will return to the lab, refine their systems, and attempt again—hopefully with less dramatic results next time.

The future of humanoid robotics will ultimately be built not by companies that succeed perfectly on the first try, but by those that fail intelligently, learn thoroughly, and iterate persistently.

Related Reading

- How Robots Use AI Vision to Understand the World in 2025

- Computer Vision in 2025: How Robots Are Transforming Manufacturing & Healthcare

- Reinforcement Learning Is Powering the Next Generation of Robotics

- Beyond Sight: How Robots Use AI to Understand the World

- Autonomous Vehicles in 2025: How Computer Vision Is Driving Safer Roads

Tags

Share this post

Categories

Recent Posts

Opening the Black Box: AI's New Mandate in Science

AI as Lead Scientist: The Hunt for Breakthroughs in 2026

Measuring the AI Economy: Dashboards Replace Guesswork in 2026

Your New Teammate: How Agentic AI is Redefining Every Job in 2026

Related Posts

Continue reading more about AI and machine learning

Physical AI Hits the Factory Floor: Beyond the Humanoid Hype

Forget the viral dance videos. In early 2026, Physical AI moved from the lab to the assembly line. With the electric Boston Dynamics Atlas beginning field tests at Hyundai, we explore the "Vision-Language-Action" models and digital twins turning humanoid hype into industrial reality.

Boston Dynamics' Atlas at Hyundai: The Humanoid Robot Era Begins

The humanoid robot era isn't coming—it's here. Boston Dynamics' Atlas just walked onto a real factory floor at Hyundai's Georgia facility, marking the first commercial deployment of a humanoid robot in manufacturing. With 99.8% reliability, superhuman flexibility, and the ability to learn new tasks in a single day, Atlas represents a fundamental shift in how factories operate. But here's what nobody's talking about: this isn't about replacing workers. It's about redefining what manufacturing jobs look like.

Computer Vision in 2025: How Robots Are Transforming Manufacturing & Healthcare

Explore the real-world applications of computer vision in robotics that are driving unprecedented advancements in manufacturing precision and healthcare outcomes in 2025.